Noshiro Plant

- Established

- 1995

- Site area

- 104,422m²

- Items manufactured

- Prescription drugs (solid dosage forms)

- Certifications obtained

- ISO14001

(Environmental management system)

Obtained in 2001

OHSAS18001

(Occupational health and safety management system)

Obtained in 2003

ISO45001

(Occupational health and safety management system)

Obtained in 2019

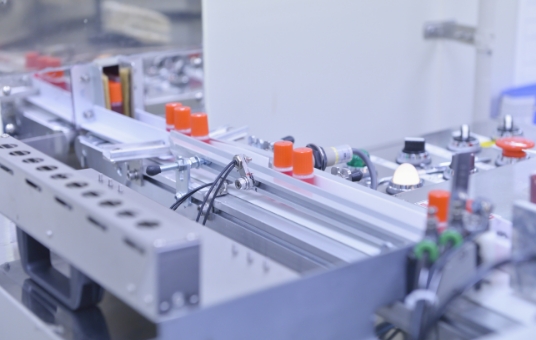

Low-cost, high-volume manufacturing.

Integrated manufacturing from active pharmaceutical ingredients to finished products.

The Noshiro Plant began operations as the pharmaceutical manufacturing plant of KYORIN Pharmaceutical, and is engaged in API (Active Pharmaceutical Ingredients) manufacturing of products developed in-house. Subsequently, as a manufacturing plant of finished products, automated transport of pharmaceutical ingredients and intermediate products, and robotic arms for labor saving have been introduced. Automation makes it possible to manufacture large volumes at a low cost with high productivity. Using these strengths, the facility has been also manufacturing generic drugs in large volumes in addition to new drugs, focusing on tablets and capsules. The plant has also achieved solid success in inspections by overseas regulatory authorities.

Takaoka Plant

- Established

- 2024

- Site area

- 42,457m²

- Items manufactured

- Prescription drugs (solid dosage forms)

The new plant is designed for greater productivity and environmental consciousness.

The Takaoka Plant has a potential to produce up to two billion solid dosage forms per year.

To save manpower, raw materials, packaging materials and finished products are stored in the automated warehouse. And the automation system is introduced to transfer intermediate products to containers and manufacturing equipment.

Manufacturing areas with powder are installed airlocks in order to avoid cross contamination.

LNG and hydropower can expect to reduce CO2 emissions by about 1/6 compared to conventional heavy fuel oil and thermal generation.

Furthermore, the manufacturing building is located in the southern half of the site to provide future manufacturing space.

Inami Plant

- Established

- 1975

- Site area

- 12,967m²

- Items manufactured

- Prescription drugs (solid dosage forms, eye drops) and OTC drugs (eye drops)

- Certifications obtained

- ISO14001

(Environmental management system)

Obtained in 2008

OHSAS18001

(Occupational health and safety management system)

Obtained in 2009

ISO45001

(Occupational health and safety management system)

Obtained in 2019

Small-lot manufacturing of numerous types of products,

focusing on generic drugs.

The Inami Plant is our primary facility for generic drug manufacturing, and began operating as a Kyorin Group plant in 2005. The plant manufactures more than 200 products, including contracted manufacturing from outside the Group. The plant’s specialty is its flexibility that enables it to manufacture small volumes of oral solid dosage forms. Visits from drug manufacturers contracting to the plant provide information that has enabled the facility to gain expertise in maintaining stable supplies of highquality products. Along with responding to the growth in demand for generic drugs seen in recent years, the facility is working with the Noshiro and the Shiga plants to create a stable supply structure, and striving for even higher productivity and reliability.

Shiga Plant

- Established

- 1977

- Site area

- 61,272m²

- Items manufactured

- Prescription drugs (drug formulations and packaging: Solid dosage forms, dry syrups. Packaging: Vials, nasal sprays) and OTC drugs (solid dosage forms)

- Certifications obtained

- ISO14001

(Environmental management system)

Obtained in 2019

ISO45001

(Occupational health and safety management system)

Obtained in 2019

Focusing on contracted manufacturing incorporating global GMP.

For many years the Shiga Plant was a manufacturing base for a non-Japanese pharmaceutical manufacturer, and in 2012 it began operating as part of the Kyorin Group. In addition to manufacturing the Group’s main products, the plant is unique for its high portion of manufacturing contracted from outside the Group, including the manufacturing of pharmaceutical products to be sold in Japan by overseas manufacturers. The plant’s manufacturing is able to keep pace with the needs of the times, having implemented global GMP since its establishment with manufacturing equipment oriented to prevent things like cross contamination, and the ongoing introduction of the latest equipment. Using its abundant experience and expertise gained from contracted manufacturing from overseas global companies, the facility is working aggressively to increase its contracted manufacturing from outside the Group.